TPU Injection Molding Machine

Features

Kinki’s full range of Vertical Injection Molding Machines is engineered to deliver stable and precise performance for TPU (Thermoplastic Polyurethane). TPU’s unique sensitivity to temperature and shear requires specialized handling—our equipment ensures accurate injection control and stable thermal management to produce high-quality parts with excellent surface finishes and elasticity.

-

Optimized Melt Flow Control

TPU requires steady melt temperature and pressure. Kinki’s vertical systems facilitate a uniform flow to eliminate defects such as bubbles or short shots. -

Consistent Injection Performance

Our high-response control ensures reliable dimensional stability and a clean surface finish, even for soft or thin-walled TPU components. -

Vertical Clamping Structure

Ideal for efficient insert placement and overmolding. The vertical design allows operators to load parts safely and quickly without disrupting cycle consistency. -

Energy-Efficient Options

Depending on the selected model, Kinki’s machines can significantly reduce power consumption while maintaining high repeatability. -

Reliable Cycle Stability

TPU molding benefits from predictable cycles. Kinki machines maintain consistent timing, contributing to lower scrap rates and higher production yield.

Applications

Charging guns for electric vehicles, car sunroofs and triangular windows, leak-proof side strips, motor stators. More automotive component manufacturing by injection molding.

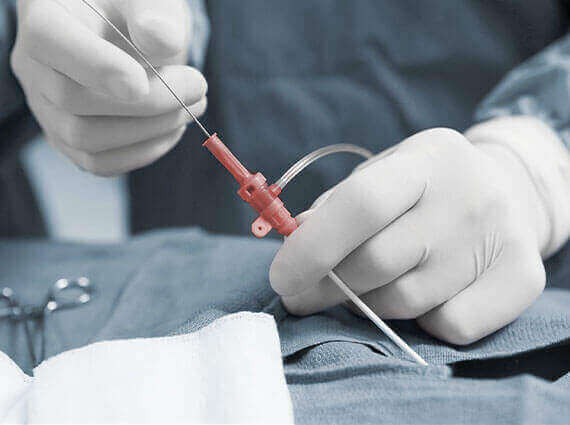

Since medical equipment is produced in a clean room, it is recommended that all motors have no pollution.

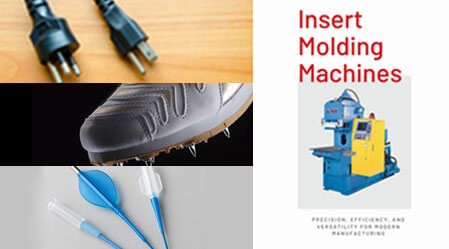

Invasive infusion tubes, blood collection needles, dialysis catheters

Sports shoe soles, POM zippers, fasteners and accessories

Screwdriver and hammer handle, two-color handle, knife handle scissors

Mobile phone and computer charging network routes, stepping motors and fan blades, precision electronic parts, sheaths and slings

Golf balls, diving respirators, gaming chips

End Products

Kinki’s TPU injection molding machines support precision overmolding, footwear traction parts, and multi-layer surface applications across sporting, automotive, and industrial sectors.

-

Overmolded Grips & Handling Components

- Soft-Touch Tool & Device Grips – Ergonomic TPU surfaces with slip resistance and handling comfort.

- Golf Club TPU Grips – Vibration-dampening overmolded designs for swing stability and control.

-

Footwear & Traction Elements

- TPU Outsoles & Cushion Modules – Wear-resistant components for athletic and performance footwear.

- Golf Cleats & Impact Pads – Turf traction elements engineered for shock absorption and ground stability.

-

Layered & Surface-Coated Parts

- TPU Ball Cover Layers – Multi-layer surface skins supporting rebound characteristics and durability.

- Protective Tech Casings – Flexible, impact-resistant housings for consumer electronics and wearables.

-

Industrial & Automotive Components

- Seals, Gaskets & Boots – Precision-molded TPU parts for oil resistance, sealing integrity, and high-flex cycles.

- Soft-Touch Medical Connectors – Biocompatible housings and ergonomic interface components.

TPU Injection Molding Machine Lineup

Kinki offers a diverse lineup of vertical machines, each customizable with Single-Slide, Double-Slide, or Rotary Table configurations to suit your specific production workflow.

| Series | Machine Type | Ideal TPU Applications | Key Advantage |

|---|---|---|---|

| KT Series | Standard Vertical | General TPU components, small-to-medium shots. | High stability & proven reliability. |

| KC Series | Tie-bar-less | Medium-sized parts & complex molds. | 3-sided open access for easy mold change. |

| KR Series | High-Tonnage | Large-scale industrial seals & thick-walled parts. | Robust clamping force & large platen space. |

| KET Series | All-Electric | Medical-grade & high-precision micro parts. | Clean-room compatible & ultimate accuracy. |

Frequently Asked Questions

Q1. Can all Kinki vertical machines mold TPU?

Yes. Kinki’s entire range of vertical thermoplastic injection machines (KT, KC, KR, KET) can be configured to mold TPU by adjusting the screw design and processing parameters to match the material's specific grade.

Q2. What machine configurations are best for TPU overmolding?

For high-efficiency overmolding (like soft-touch grips), we recommend Rotary Table or Double-Slide models. These allow the operator to load inserts on one side while the machine molds on the other, maximizing output.

Q3. Does Kinki provide specialized screws for TPU?

Yes. Depending on your material's hardness and viscosity, we provide optimized screw and barrel sets to ensure the best melt homogenization without overheating the TPU.

How Does a TPU Injection Molding Machine Work?

TPU is celebrated for its elasticity and durability, but it is also a "temperamental" material. Successful molding requires precise control over the following stages:

-

Moisture Control

As TPU is highly hygroscopic, Kinki systems offer seamless integration with auxiliary drying equipment to eliminate moisture-related defects like bubbles or silver streaks. -

Precision Plasticization

Using a specialized screw geometry, Kinki’s machines ensure uniform melting. This prevents over-shearing, which can cause material degradation, yellowing, or loss of physical properties. -

Vertical Injection Accuracy

Our precision hydraulic or electric systems provide high-response control over injection speeds, ensuring even cavity filling—even for complex, thin-walled designs. -

Stable Clamping & Thermal Management

Since TPU stays flexible longer than other plastics, Kinki’s temperature-controlled molds and stable clamping ensure the part solidifies perfectly before ejection, maintaining strict dimensional tolerances. -

Efficiency via Table Systems

Leveraging Rotary or Slide Table configurations, the operator can safely load inserts during the cooling phase, creating a synchronized, high-efficiency production loop ideal for overmolded components.

Why Choose Kinki Vertical Machines for TPU?

Kinki Machinery provides dependable vertical injection solutions built on decades of hands-on engineering and real manufacturing experience. Our machines are designed for stability, precision, and long-term production efficiency.

-

Stable Cycle Timing

Predictable cycles lead to lower scrap rates and higher ROI. -

Flexible Configurations

Choose from slide or rotary tables to optimize operator ergonomics and safety. -

Proven Durability

Built with Taiwanese engineering excellence and over 30 years of specialization in vertical molding.

Partner with Kinki Machinery

With over 1,400+ installations worldwide, Kinki Machinery provides dependable solutions built on decades of hands-on engineering.

Need a Custom TPU Molding Solution? Contact our technical experts today to find the ideal machine configuration for your production needs.