Our products are sold to major markets around the world including Southeast Asia, Japan, Europe, North America and South America. There is no secret to the "Taiwan economic miracle" it comes from the basic willingness of the people of Taiwan to compete fiercely and to strive toward progress in everything that we do.

About Us

Brand Story

To Make Taiwan Kinki Synonymous with the Most Advanced Machinery Technology in Taiwan.

Lines of Business

-

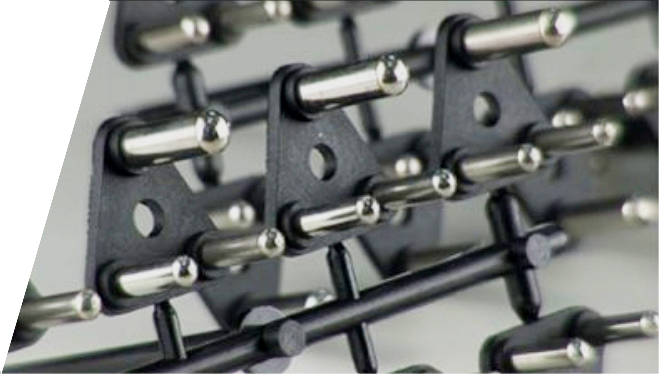

01Production of vertical plastic injection molding machines.

-

02Design of automatic injection machinery.

-

03Turn-key plants for accessories and peripherals for injection machinery.

-

04Injection mold design and manufacturing.

-

05Electrode position, power coating, baking enamel, and leather treatment.

-

06Agency of vertical model injection machine and Zinc alloy coating.

History

Taiwan Kinki Machinery was established in Taipei in 1983 and specializes in vertical plastic injection molding machinery. Since our founding we have worked to build our brand, improve our technology and develop a full line of machinery.

In 1991 we opened a second factory at DONG-GOAN in Mainland China. This factory has greatly expanded the scope of our operations through large-scale production, high quality and greater competitiveness in international markets.

In 1996 we began production in our third factory at Hsin-chu in Taiwan. This plant takes advantage of Taiwan's valuable manpower and assures that we can continue to contribute the people of Taiwan by developing automated equipment and diversified operations. The Hsin-chu Factory includes an old-making section, an electroplating section and a complete plant planning section to offer our clients an ever-wider range of services.

Outstanding results

Quality Assurance

According to the aforementioned goals and concepts of management, Taiwan Kinki Machinery has been continuously improving its internal quality standards, fostering a quality-conscious culture, enhancing processes, and upgrading analytical instruments. We successfully attained ISO9001:2000 certification in July 2003. We firmly believe that these achievements constitute the most compelling assurance for our customers.

We, at Taiwan Kinki Machinery, believe that meeting customer requirements and gaining customer trust are essential for business growth. To achieve this goal, we must implement effective quality management strategies that enhance efficiency, improve quality, reduce costs, and minimize product delays. Additionally, by elevating the level of service, we can enhance our competitiveness and thrive in today's dynamic economic landscape.