Vertical Rubber Injection Molding Machines

_pic.jpg)

Features

Discover what makes our machines exceptional: precision engineering, compact vertical design, and TÜV-certified energy efficiency built into every model.

Precision Injection System

- Servo-driven control with ±0.5% shot accuracy

- Three-stage profiling: Fill, Pack, Hold

- Optional cavity pressure monitoring for critical parts

Space-Saving Vertical Clamping

- Saves up to 40% floor space

- Gravity-assisted mold alignment improves repeatability

- Tooling changeover under 10 minutes

Energy Efficiency

- TÜV-certified: only 0.55 kWh/kg power consumption

- Regenerative braking and mold preheat recovery

- Compatible with eco-friendly silicone injection molding

These features aren’t just numbers—they translate into real-world performance advantages. To learn how these design features compare to other molding methods, check out our guide on Everything About Rubber Injection Molding and Overmolding Solutions.

Applications

Charging guns for electric vehicles, car sunroofs and triangular windows, leak-proof side strips, motor stators. More automotive component manufacturing by injection molding.

Polarized lenses for sunglasses, motorcycle goggles, backlight panels, light guide panels, LED lamp wire frames

Since medical equipment is produced in a clean room, it is recommended that all motors have no pollution.

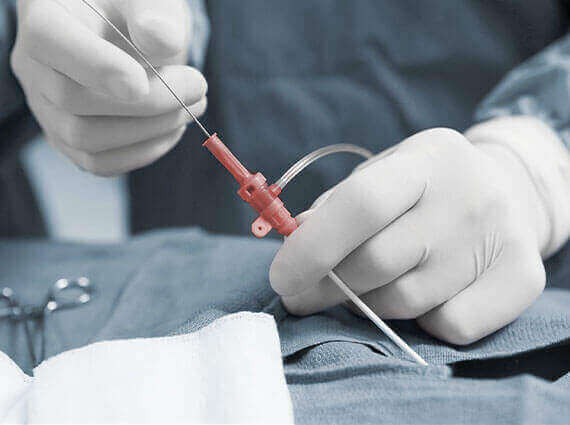

Invasive infusion tubes, blood collection needles, dialysis catheters

Sports shoe soles, POM zippers, fasteners and accessories

Screwdriver and hammer handle, two-color handle, knife handle scissors

Bakelite (thermoset) plastic materials are generally used for kitchen utensils because of the need for high temperature resistance. Therefore, the machine clamping force required is relatively high. The most commonly used models are TKC's KR-series.

Heat-resistant pan handles, plugs and sockets, planers and scrapers

Toothbrush, cosmetic laminate tube, earplugs and goggles

Mobile phone and computer charging network routes, stepping motors and fan blades, precision electronic parts, sheaths and slings

End Products

_pic.png)

Vertical Rubber Injection Molding Machines | Precision Vertical Molding Solutions

Kinki Machinery designs and manufactures high-precision vertical rubber injection molding machines for the demanding needs of the automotive, medical, and electronics industries. With over 40 years of experience, we deliver servo-controlled injection, tight mold temperature control, and energy-efficient operation to ensure consistent, high-quality rubber production. Whether you're producing silicone seals, EMI gaskets, or FDA-grade rubber parts, our solutions offer the repeatability, flexibility, and durability you need.To meet different production challenges, we offer the following vertical rubber injection molding machine series.

Vertical Rubber Injection Molding Machine Lineup

Explore our full range of rubber injection molding machine models, each optimized for specific molding needs—from small medical parts to large automotive components.

| Series | Model Type | Key Features | Best For | Product Page |

|---|---|---|---|---|

| KR Series | Vertical Clamp / Horizontal Injection | Heavy-duty frame, long stroke, horizontal injection | Large rubber parts, high-pressure components | View KR Series |

| KC Series | Tie-Bar-Less Vertical Clamp | Compact design, 3-side access | Mid-sized parts, space-constrained layouts | View KC Series |

| KT Series | Compact Vertical Clamp / Vertical Injection | Includes: KT / KT-D / KT-DM / KT-R | Insert molding, small to medium parts, multi-station workflows | View KT Series |

| KET Series | All-Electric Vertical | Oil-free, cleanroom-ready, energy-efficient | Medical-grade, food-safe, low-energy production | View KET Series |

| Special-Purpose | Custom Vertical Solutions | Tailored machine design, rubber/plastic hybrid options | Unique geometries, automation, hybrid molding | Explore Custom Machines |

Want to understand how vertical molding techniques impact machine design and performance? Automotive Rubber Injection Molding: A Deep Dive into Vertical Techniques explores it in depth.

Applications & Industries

Our rubber injection machines power production across industries—from automotive to medical—ensuring quality, compliance, and performance at every stage. From automotive to medical, each industry has unique performance and compliance requirements.If you're evaluating which material or molding process best suits your application, check out Difference Between Liquid Silicone Rubber and Rubber Injection Molding for useful insights.

Automotive

- Turbo seals, shock absorber bushings

- Battery gasket and IP67-rated EV silicone parts

Medical

- ISO Class 8 cleanroom compatibility

- FDA-grade silicone and LSR components

Electronics & Industrial

- EMI/RFI gaskets, waterproof seals

- Rubber-to-metal bonding, flame-retardant rubber molding

Frequently Asked Questions

Get quick answers to common questions about performance, materials, and automation when working with Kinki’s vertical rubber injection molding systems. Here are some of the most common questions we receive from manufacturers and engineers.

Machine Performance

Q: What clamping force ranges are available?

Standard models: 15–500 tons; custom models up to 800 tons.

Q: What’s the shot precision?

Injection repeatability is ±0.01 mm; temperature control ±0.3 °C.

Q: What is the cycle time?

Typical cycle time ranges from 30–60 seconds, depending on part geometry and material.

Material Compatibility

Q: Can I mold carbon-filled or fiber-reinforced rubber?

Yes, with enhanced screw/barrel wear resistance for abrasive compounds.

Q: Which rubber materials are supported?

EPDM, NBR, FKM, and LSR are all supported.

Q: Max filler content?

Up to 60% filler in high-torque configurations.

Automation & Maintenance

Q: What automation standards are supported?

EUROMAP 67 and SEMI E54.1 compatible with most robots.

Q: Predictive maintenance available?

Yes, with IoT-enabled service reminders based on cycles.

Q: Hydraulic oil change frequency?

Every 10,000 cycles or annually, whichever comes first.

Having trouble with your current setup?

Don’t miss our Troubleshooting Guide: 4 Most Common Problems and Solutions Regarding Rubber Vertical Injection Molding Machines.

For full specs, visit our Vertical Injection Molding Machine.

How Does Vertical Rubber Injection Molding Work?

A quick primer on the rubber injection process to help you understand why it’s the go-to method for precision elastomer molding.

Want to better understand how rubber injection molding works behind the scenes? Here's how:

Rubber injection molding involves heating elastomer compounds and injecting them under pressure into a mold cavity. Unlike compression molding, this process offers higher precision, better repeatability, and faster cycles. It is ideal for producing complex geometries and high-volume rubber parts, especially in rubber molding for automotive and cleanroom applications.

Why Choose Kinki Machinery?

Kinki delivers dependable solutions backed by decades of engineering expertise, trusted by manufacturers worldwide.

That’s where Kinki’s decades of experience and engineering precision come in.

- 1,400+ installations worldwide

- Precision Taiwanese-German engineering

- Global spare parts & service support

- Over 30 years of proven innovation

- Trusted rubber injection molding machine manufacturer

Explore our company profile to learn more.