Insert Molding Machine

Features

Our Insert Molding Machines are designed for stable, precise, and efficient molding of plastic materials around metal inserts, threaded components, electronic elements, and embedded parts. Built on Kinki’s proven vertical injection platform, these machines support accurate insert positioning, consistent molding cycles, and reliable production performance across a wide range of applications.

-

Vertical Clamp & Injection Design

The gravity-friendly vertical structure is ideal for keeping inserts securely in place during mold closure, significantly reducing the risk of part displacement compared to horizontal machines. -

Wide Tonnage Coverage

From compact precision units to heavy-duty models, our lineup supports everything from micro-connectors to large-scale industrial hybrid assemblies. -

Stable Injection Control

Advanced hydraulic or electric systems ensure a consistent melt flow around pre-positioned inserts, preventing damage to delicate components while achieving clean, flash-free results. -

Flexible Automation Compatibility

Designed for versatility, our machines integrate seamlessly with manual loading, robotic arms, or fully automated vibratory bowl feeders. -

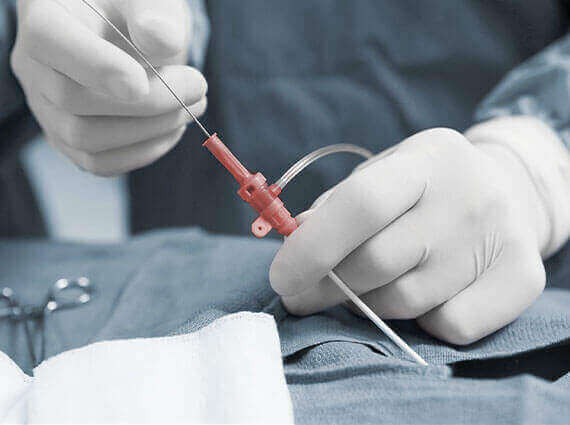

KET Series All-Electric Options

For medical and high-tech sectors, our all-electric models provide ultra-quiet operation, micron-level repeatability, and significantly reduced energy consumption.

Applications

Charging guns for electric vehicles, car sunroofs and triangular windows, leak-proof side strips, motor stators. More automotive component manufacturing by injection molding.

Since medical equipment is produced in a clean room, it is recommended that all motors have no pollution.

Invasive infusion tubes, blood collection needles, dialysis catheters

Screwdriver and hammer handle, two-color handle, knife handle scissors

Mobile phone and computer charging network routes, stepping motors and fan blades, precision electronic parts, sheaths and slings

End Products

-

Integrated Connectors

: Waterproof electrical plugs and multi-pin terminal blocks with metal pins securely embedded. -

Threaded Fasteners

: Plastic knobs, handles, and enclosures featuring durable brass or stainless steel threaded inserts. -

Overmolded Tooling

: Screwdrivers, wrenches, and medical instruments with ergonomic plastic grips molded over metal cores. -

Hybrid Automotive Parts

: Bushings, brackets, and sensor housings that combine the strength of metal with the chemical resistance of plastic. -

Electronic Modules

: Encapsulated PCBA (Circuit Board) housings that protect sensitive electronics from environmental stress.

Insert Molding Machine Lineup

Kinki offers a diverse lineup of vertical machines, each customizable with Single-Slide, Double-Slide, or Rotary Table configurations to suit your specific production workflow.

| Series | Machine Type | Key Strengths | Typical Applications |

|---|---|---|---|

| KT Series | Standard Vertical | Compact footprint; versatile Slide/Rotary table options. | Connectors, sensors, small appliance parts. |

| KC Series | Tie-bar-less | 3-sided mold access; ideal for complex or oversized molds. | Mid-sized housings, long inserts, appliance parts. |

| KR Series | High-Tonnage | Heavy-duty frame; high injection volume for large components. | Automotive hybrid parts, large industrial inserts. |

| KET Series | All-Electric | Ultimate repeatability; clean-room compatible; eco-friendly. | Medical inserts, high-precision electronics. |

| Customized | Special Purpose | Tailored configurations for non-standard production needs. | Mixed-material projects, specialized inserts. |

Frequently Asked Questions

Q1. Why is a vertical machine better than a horizontal machine for insert molding?

Gravity is the main advantage. In a vertical machine, the insert sits securely in the bottom mold half. In a horizontal machine, inserts can easily fall out or shift during mold closure, leading to high defect rates.

Q2. Can I automate the insert loading process?

Absolutely. Kinki machines are designed with open access, making them highly compatible with 6-axis robots or Cartesian pick-and-place systems to increase production speed and safety.

Q3. Does insert molding help reduce costs?

Yes. By molding the plastic directly onto the insert, you eliminate the time and labor costs associated with post-molding assembly, such as gluing, sonic welding, or manual fastening.

How Does Insert Molding Work?

The insert molding process involves placing a pre-manufactured component (the "insert") into the mold before injecting plastic.

- Placement: The operator or robot places the insert (metal, ceramic, or plastic) into the mold cavity. In Kinki’s vertical machines, gravity helps the insert stay perfectly seated.

- Clamping: The machine’s vertical clamping unit closes with precision, ensuring the insert is not crushed or shifted.

- Injection: Molten plastic is injected at controlled pressures, flowing around the insert to create a robust, mechanical, or chemical bond.

- Cooling & Ejection: After a brief cooling phase, the unified, single-piece component is ejected, ready for use without the need for secondary assembly.

Why Choose Kinki Vertical Machines for Insert Molding?

Our vertical Insert Molding Machines deliver:

-

Proven Stability

: Over 40 years of engineering ensures consistent clamping and injection performance. -

Maximized Safety

: Advanced light curtains and safety interlocks protect operators during manual loading. -

Flexible Configurations

: Choose from Single/Double Slide or Rotary Table models to optimize your cycle time—mold one part while loading the next.

Whether producing small precision components or large insert-integrated parts, our machines provide a dependable and versatile platform for high-quality insert molding.

Request a quote or consultation to choose the ideal insert molding machine based on your inserts, materials, and production needs.